Department of Mechanical Engineering

The Department of Mechanical Engineering

Is for students...

who are innovative thinkers who want to master the world of machines. Students should have strong mathematical and analytical skills to understand how machines can be used as drivers of innovation. This course is for those who are looking for a cutting-edge exploration of physics, mathematics, and thermodynamics to create machines and technologies that drive innovation across borders and sectors.

To Become...

- an aerospace engineer

- an automotive engineer

- a control & instrumentation engineer

- a maintenance engineer

- an analytical engineer

- a design engineer

- a test engineer

- a manufacturing engineer

- a development engineer

- a research engineer

- a sales engineer

- an engineering manager

- a consulting manager

The Department of Mechanical Engineering was established in 1997 with an annual intake of 60 students in the undergraduate programme and has grown by leaps and bounds since its inception. The annual intake was increased to 90 in 2009, 120 in 2013 and 180 in 2018. The post-graduate programme in Robotics and Mechatronics was started during the academic year 2022-23. A well-planned block of 4243 square meters on three floors is self-sufficient with excellent infrastructural facilities. Currently, the department is under the able guidance of Dr. Vinay K B.

The Department of Mechanical Engineering has state-of-the-art laboratories, these laboratories not only satisfy the curriculum requirements of the students very lucidly but also provide additional facilities to enhance the practical knowledge. It has excellent computing facilities and resources in terms of both hardware and software. The department has 250 computers installed with a wide range of commercially available software packages. It has the ISHRAE-VVCE showcase, the first of its kind in Karnataka.

The department has able and dedicated faculty members from all specializations of mechanical engineering. The faculty members are not only qualified and experienced but have admirable adeptness, service-mindedness and versatility in both teaching and research. 26 faculty members have their doctoral degrees, and 10 faculty members are pursuing Ph. D. The Department is extremely proud to have a Research Center recognised by Visvesvaraya Technological University (VTU), Belagavi.

Vision

The Department of Mechanical Engineering shall be a renowned center for quality education and research, creating competent engineers to serve the society

Mission

- To impart principles and applications of mechanical engineering through effective teaching-learning methods, competent staff and best-in class infrastructure

- To promote industry-institute interaction for mutual benefits

- To foster quality research environment in key areas

- To inculcate professional ethics, leadership qualities and entrepreneurial skills

Department Highlights

All highlights »Student Clubs

Resources

| Semester | Subject Code | Subject | Link |

|---|---|---|---|

| IV | 18MEL47A | Material Testing Lab | https://tinyurl.com/18MEL47A |

| 18MEL47B | Mech. Measurements and Metrology Lab | https://tinyurl.com/18MEL47B | |

| VI | 17MEL67 | Heat Transfer Lab | https://tinyurl.com/17MEL67A |

| 17MEL68 | Modeling and Analysis Lab | https://tinyurl.com/17MEL68 |

Scheme & Syllabus

Program Educational Objectives (PEO’s)

Graduates of the program will:

PEO1. Apply the necessary mathematical and scientific knowledge as well as managerial and Mechanical Engineering procedures to analyze and solve real world problems within their work

domain.

PEO2. Innovate, adopt and contribute to technologies and systems in the key domains of

Mechanical Engineering

PEO3. Communicate effectively as members and leaders of multicultural and multidisciplinary teams

PEO4. Be sensitive to professional and societal contexts and committed to ethical action

Program specific outcomes (PSO)

Students graduating from the Department of Mechanical Engineering will

PSO1. Apply principles of machine design, manufacturing, thermal engineering and management to

identify, formulate and solve real life problems in various fields of engineering

PSO2. Use professional engineering practices and strategies for the development, operation and

maintenance of mechanical systems/processes

Program Outcomes (PO’s) based on NBA graduate attributes

Engineering Graduates will be able to:

- Engineering Knowledge: Apply the knowledge of mathematics, science, engineering, fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional Engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics: Apply ethical principles and commit professional ethics and responsibilities and norms of the engineering practice.

- Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in Multi-disciplinary environments.

- Lifelong learning: Recognise the need for, and have the preparation and ability to engage in independent and lifelong learning in the broadest context of technological change.

Teaching Staff

Non-Teaching Staff

Past Events

Mechanical Engineering

Mechanical Engineering

Research & Development

Our Mechanical Engineering department is good for research excellence and home to some of the well-known research workers. Our focus area of research work helps in solving real-world problems through a huge network of partnerships and collaborations. The breadth and interdisciplinary nature of our research sparks imaginative and inventive insights and solutions.

There are about 10 research supervisors in our department and 23 research scholars.

Research Guide & Scholar Details

Research Supervisor Details

Paper Publication By Faculty Members

Paper Publication By Students

Universal Testing Machine

Fully Integrated Universal Testing Machine including

- +/-50kN Self Reacting Vertical Load Frame with

- LPM power pack includes

- Operating pressure of 210bar

- Operates on single phase/ three phase 230V power supply

- Safety interlocks for the power pack

- Ports and adaptors to connect Hydraulic lift and clamp cylinders

- External cooling tower.

- Digital Servo Controller including/ensuring type

- General purpose application software capable of

- Performing Static Test

- Performing Dynamic Test

- Performing Multi Step Programming

- Export data to Excel format and plot graph

Bottom Pouring Type Stir Casting Machine (Al-Mg)

A special designed furnace in which pouring of melt into the mould happens from its bottom through a remote control switch. This type of furnace does not require the user to lift and pour the melt into the mould.

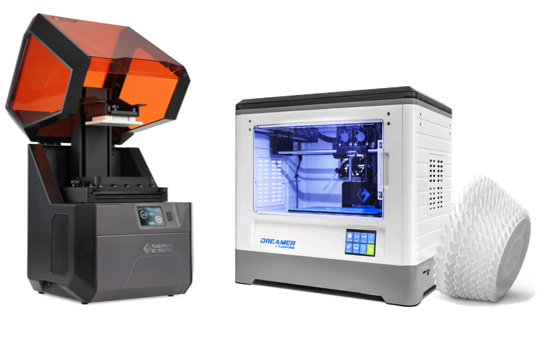

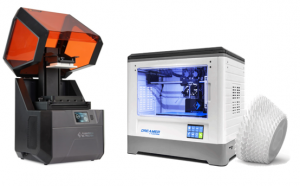

Rapid Prototyping Lab

Our department also host a RAPID PROTOTYPING LAB. The purpose of the RP Lab is to allow students access to current manufacturing technologies in their course work, independent projects, and research. The RP Lab is used heavily by courses in the engineering mechanics and mechanical engineering curriculum. This technology is capable of printing out concepts and ideas into Three-Dimensional (3D) physical models. This additive manufacturing technique allows us to build complex geometries and shapes with ease which is otherwise very difficult or impossible to be produced using conventional manufacturing techniques. Lab consists of Digital Light Processing 3d Printer, Dual Extruder, Matter & Form.

MODEL QUESTION PAPERS

RESOURCES

| SEMESTER | COURSE TITLE | FACULTY | LINK |

| I/II | Sources of Energy, Thermodynamics and Steam Formation | Dr.Vinay K B | https://www.youtube.com/watch?v=OnA0F5M0aDc&list=PLcwp2fRcIXJV53xiKUCwasyO-bSPp0ZS8 |

| I/II | Turbines and Pumps | Dr. Nithyananda B S | https://www.youtube.com/watch?v=qREGjqcmtoY&list=PLcwp2fRcIXJV53xiKUCwasyO-bSPp0ZS8&index=9 |

| I/II | IC Engines | Dr. S A Mohankrishna | https://youtu.be/VDq32Y3dGow

|

| I/II | Machine Tools, Automation and Robotics | Dr. Khalid Imran | https://www.youtube.com/watch?v=UppyO8ocxnA&ab_channel=VTUe-ShikshanaProgramme |

| I/II | Machine Tools | Dr. Khalid Imran | https://www.youtube.com/watch?v=UppyO8ocxnA&t=565s&ab_channel=VTUe-ShikshanaProgramme |

| IV | Kinematics of Machines | Prof. Mamatha Y P | https://youtube.com/playlist?list=PLcwp2fRcIXJVX6xk8WZaAnF4ocmLcL4yJ

|

| IV | Kinematics of Machines | Prof. Gurudatt H M | https://youtube.com/playlist?list=PLcwp2fRcIXJVX6xk8WZaAnF4ocmLcL4yJ

|

| IV | Material Testing Lab | Dr. Shivashankar R | https://drive.google.com/drive/folders/1LLfS2GDXYoTgnGJPbL93RiKuGt4ZpHf_ |

| IV | Mech. Measurements and Metrology Lab | Prof. Amruth E | https://drive.google.com/drive/folders/1Dfov6WyeYktyAbSTb8Nqk0Wxe7pB8zuX |

| V | Fluid Power Engineering | Dr. Rishi J P | https://www.youtube.com/watch?v=ZB7yXmVq_tU&list=PLcwp2fRcIXJX0J6QhLUQPbYc5zYZPkMf4&index=2&t=1512s |

| V | Fluid power Engineering Directional Control Valves | Dr. Ravi K S | https://www.youtube.com/watch?v=AjE3J0JslDI&list=PLcwp2fRcIXJX0J6QhLUQPbYc5zYZPkMf4&index=17&t=1801s |

| VI | Heat Transfer Lab | Prof. Muthuraju N P | https://drive.google.com/drive/folders/1OY87s1xs_ojPebbIFQbe35ys_QBVw8Gu |

| VI | Modeling and Analysis Lab | Prof. Chandan V | https://drive.google.com/drive/folders/1Svr4htY5RE6QjvB1bY_7qBQS1jAamVc2 |

Laboratories

Basic Workshop

Mechanical Engineering Workshop is a place where students acquire knowledge on the operation of various processes involved in manufacturing and production. The Workshop Practice course makes students competent in handling practical work in engineering environment.

Major Equipment’s /Machines in the Lab

- Air Cooled Welding Machine

- Oil Cooled Welding Machine

- Drilling Machine

- Grinding Machine

Floor Area: 203 Sq.m

CAED Lab

Computer-aided engineering drawing is a technique where engineering drawings are produced with the assistance of a computer along with manual drawing and it is only the graphical means of representing a design.

Major Equipment’s /Machines in the Lab

- 80 DELL Computers Systems(TFT)

- IBM Server

- Multimedia Projector

- A4 Printer

- Software : Solid edge

Floor Area: 221 Sq.m

Metallography and Material Testing Laboratory

In this lab students are made to understand material properties through laboratory experiments

Major Equipment’s /Machines in the Lab

- Universal Testing Machine of 60 MT Capacities.

- Torsion Testing Machine

- Fatigue Testing Machine

- Impact Testing Machine (Izod & Charpy)

- Hardness Testing Machine (Vicker’s & Rockwell’s)

- Ultrasonic Flaw Detector

- Magnetic Crack Detector

- Die Penetrant Test Kit

Floor Area: 89 Sq.m

Foundry

To equip the students with general and practical knowledge in field of molding mixture preparation, molds, castings production and with the methods of solving of technological and metallurgical problems at the level of recent knowledge of the branch.

Major Equipment’s /Machines in the Lab

- Permeability test on foundry sand

- Universal Sand Testing Machine

- Sieve Analysis Testing Machine

Floor Area: 133 Sq.m

Machine Shop

Machine shop work is generally understood to include all cold-metal work by which an operator using power driven equipment to remove a portion of the metal and shapes it to some specified form or size.

Major Equipment’s /Machines in the Lab

- CNC Lathe

- Conventional engine Lathes

- Radial Drilling Machine

- Milling Machines

- Shapers

Floor Area: 270 Sq.m

Forging Lab

To provide students with the knowledge and necessary skills to perform forging operations

Major Equipment’s /Machines in the Lab

- Al-Mg Stir Casting Equipment

- LPG Furnaces with accessories (2 nos)

- 5 HP Blower

- Anvils

- Conventional forges

- Cupola Furnace

Floor Area: 111 Sq.m

Fluid Mechanics & Machinery Lab

Fluid mechanics and Fluid machines labs have all new comprehensive experimental set ups catering to the requirements of curriculum. The laboratories cater to the needs of mechanical students in the subject of fluid mechanics and fluid machines. It strengthens and broadens the students’ knowledge of incompressible fluid mechanics.

Major Equipment’s /Machines in the Lab

- Francis Turbine

- Kaplan Turbine

- Pelton Wheel

- Reciprocating & Centrifugal Pump Test Rigs

- Reciprocating Compressor

- Centrifugal Blower.

Floor Area: 133 Sq.m

Energy Conversion Lab

This lab will help students to see how energy can be converted from one form to another. Students will observe the loss in useful energy as a result of such a conversion and measure the efficiency for such conversions.

Major Equipment’s /Machines in the Lab

- Viscometers (Redwood, Saybolt & Torsion)

- Bomb & Boys Calorimeter

- Flash & Fire point experimental setup

- Carbon Residue test setup

- stroke Diesel Engine Test Rig

- 2 Stroke Petrol Engine Test Rig

- Multi Cylinder Petrol Engine

- Variable Compression Petrol Engine

- Planimeter

Floor Area: 69 Sq.m

Heat & Mass Transfer Lab

This laboratory course will reinforce the students’ understanding of the analysis of applications pertaining to Heat and Mass Transfer through suitably designed experiments.

Major Equipment’s /Machines in the Lab

- Thermal Conductivity of Insulating Powder, Metal Bar, Lagged Pipe, Composite Walls.

- Emissivity Test rig

- Heat Exchanger

- Free & Forced Convection Test Rigs

- Pin Fin Test Rig

- Refrigeration and Air conditioning Test Rigs

- Critical Heat Flux

- Stefan Boltzmann apparatus

Floor Area: 100 Sq.m

CIM & CAMA Lab

The objective of this lab is to introduce computerized manufacturing systems and modeling analysis to the Mechanical Engineering students.

Major Equipment’s /Machines in the Lab

- 20 DELL Computer Systems(TFT)

- 20 Intel Core 2 Duo Computers

- Modeling and Analysis Software:

- Catia, Ansys, Cadem, AMESIM

Floor Area: 76 Sq.m

Design Lab

To demonstrate the concepts discussed in Design of Machine Elements, Mechanical Vibrations & Dynamics of Machines courses.

Major Equipment’s /Machines in the Lab

- Journal Bearing Test Rig

- Polariscope

- Spring Mass System

- Hartnell Governor Test Rig

- Balancing of Rotating Masses

- FFT Analyzer

- Strip Mass System

- Gyroscope

Floor Area: 83 Sq.m

Seminar Hall

Seminar Hall equipped with AC and audio visual equipment

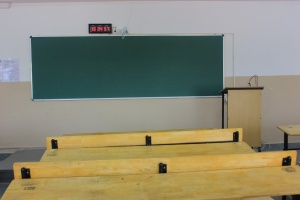

Class Rooms

The department complex hosts classrooms of various sizes from a large seminar hall to small tutorial rooms. Booking of regular lecture slots is done by the department academic office. Faculty and certain other officers can book free slots for additional lectures or other academic activity. Each classroom is well equipped with blackboard, LED projectors, lecture capture cameras and good seating arrangements for students. Departmental library, Seminar Hall, lift, 24*7 Wi-Fi facilities & one common room for boys are the highlights of the department.

Tutorial Rooms equipped with multimedia Projectors , CCTV & impartus Video Lecture recording

HOD’s Room, Faculty Rooms & Department Office

Department Library

Established Dept. Library to cater the needs of students with more than 1000+ volumes

Additional Facilities

Rapid Prototyping Lab:

| Sl. No. | Name of the Equipment | Specification | Reason (s) for creating facility | Areas in which students are expected to have enhanced learning | Relevance to PO’s & PSO’s |

| 1 | 3-D Printer (FDM) | Make: Think 3D

Flash Forge Dreamer Dual Extruder |

|

|

PO1, PO3, PO4, PO5, PO9, PO11, PO12

PSO1, PSO2 |

| 2 | 3-D Printer (SLA) | Make: Think 3D

Flash forge Hunter DLP 3D Printer |

|||

| 3 | 3-D Scanner | Make: Think 3D

Matter & Form |

Fabrication Shop:

| SL NO | PARTICULARS | Reason(s) for creating Facility | Areas in Which students expected to have enhanced learning | Relevance to PO’s & PSO’s |

| 1 | Work bench (4’x8’) | 1. To help students in timely completion of the project work.

2. Fabrication of models required for attending competitions. 3. To create models for enhanced learning. |

1. Use of hand tools.

2. Metal Joining Process. |

PO1, PO3, PO4, PO9, PO11, PO12

PSO1, PSO2 |

ISHRAE LAB(Industrial Additional Lab Facility, Mysuru chapter)

- Showcasing and demonstration of various components related to Refrigeration and Air conditioning.

- Gaining of engineering knowledge and arousing interest in the field of Refrigeration and Air conditioning

CLIC (Collaborative Learning and Innovation Center)

The Department of Mechanical Engineering in collaboration with Dassault Systems, France and EDS Technologies, Bengaluru, proudly announces the launch of Collaborative Learning and Innovation Center (CLIC).

This Center aims to enhance the knowledge and skill of Mechanical Engineering students in different design domains, by the virtue of which students can be better engineers so as to serve the society and the nation.ning and Innovation Center)

M.Tech in Robotics and Mechatronics

Master of Technology in Robotics and Mechatronics is a two-year postgraduate programme started in the year 2022-23. The program will provide an excellent academic and research knowledge to enrich the students in next generation automation and robotics technology. The program curriculum includes concepts of Mechanical Engineering, Electronics & Communication Engineering, Electrical Engineering, Instrumentation Engineering and Computer Science Engineering to expose the students to the innovation of new technologies happening in various engineering domain. Further skill development training, Industrial training and societal projects are introduced to equip the students in the field of Robotics and Mechatronics. Students are provided with an opportunity to supplement their learning through various platforms viz., Swayam, NPTEL, Udemy, edX, Coursera and so on.

Career Opportunities:

Master of Technology in Robotics and Mechatronics will prepare the students industry ready and they can find ample of opportunities in various sectors viz., Mining, Manufacturing, Military, Health, Research, Hospitality, Space, and other related sectors. Also, the graduates may pursue Ph.D degrees in reputed National and International Institutes / Universities in the field of Robotics and Mechatronics.

Duration:

Two Years

Eligibility:

Bachelor’s degree in Engineering or Technology in Mechanical Engineering/ Automobile Engineering/Industrial & Production Engineering/ Industrial Engineering & Management/ Manufacturing Science & Engineering/ Automation & Robotics Engineering/Aeronautical Engineering/ Robotics Engineering/Mechatronics/ Electrical & Electronics Engineering/ Electronics & Communication Engineering/Tool Engineering/ Production Engineering/ Aeronautical Engineering/ Aerospace Engineering/ Electronics & Instrumentation Engineering/ Instrumentation Technology/ Mining Engineering/ Telecommunication Engineering/ Medical Electronics, with a minimum of 50% in aggregate of all the semester. AMIE in appropriate branch, GATE/PGCET qualified.

Program Outcomes:

- An ability to independently carry out research /investigation and development work to solve practical problems.

- An ability to write and present a substantial technical report/document.

- An ability to develop, operate and maintain mechatronics & robotic systems/processes using professional engineering practices and strategies.

Contact us

Get in touch with us. We are always happy to help you out

Awareness Programme

Awareness Programme on Energy Conservation

The Department of Mechanical Engineering in association with Karnataka Renewable Energy Development Limited (KREDL) organized an awareness programme on Energy Conservation. Sri Dinesh Kumar D K, Technical Officer, KREDL delivered a talk on Energy Conservation and Quiz was conducted for students.

Learn more »Outreach Programmes

Outreach Programme

Demonstration of RC Aircraft and All-Terrain Vehicle (ATV) at various schools and colleges conducted by Members of Team Vymanika & SAE BAJA of Dept, of Mechanical Engineering VVCE Mysuru.

Learn more »

GATE 2022 Free Online Training Programme

Department of Mechanical Engineering successfully conducted 8-week Free online Training Programme for aspirants of GATE 2022 Exam from 15th November 2021 to 10th January 2022.

Learn more »Workshop

RC Aircraft Design and Modelling

A two-day hands-on workshop on “RC Aircraft Design and Modelling” was organized by Vymanika Club of Department of Mechanical Engineering on 7th and 8th February 2022.

Learn more »CET Code: E071 | COMED-K Code: E147 Apply now